Today in France, Richard Mille announces another winning watch: the three-quarters-of-a-million-dollar RM27-03 Rafael Nadal Tourbillon timepiece. The two have had a collaboration for seven years now, and Richard Mille regularly pulls out all the stops for the tennis player when it comes to shock resistant tourbillon movements and outrageous designs using high-tech materials. Now we witness it again with the unveiling of this watch.

Aesthetically, the watch recalls the clay court of Roland-Garros, where Nadal, a nine-time winner of the French Open, works his magic. Thus, the hues of red and striking yellow come into play. Additionally, like the high-tech clay courts, the watch case is made of Quartz TPT(R) — achieved by impregnating fine layers of silica just 45 microns thick with tinted resin according to a proprietary process developed in Switzerland. That process stacks the filaments in layers before heating them to 120 °C.

The new Richard Mille RM27-03 Rafael Nadal Tourbillon is made with high-tech materials and is super light in weight.

According to Richard Mille, achieving a new shade of Quartz TPT® without compromising biocompatibility and durability is no easy feat. The work was achieved in tandem with the engineers at Richard Mille and North Thin Ply Technology (NTPT®).

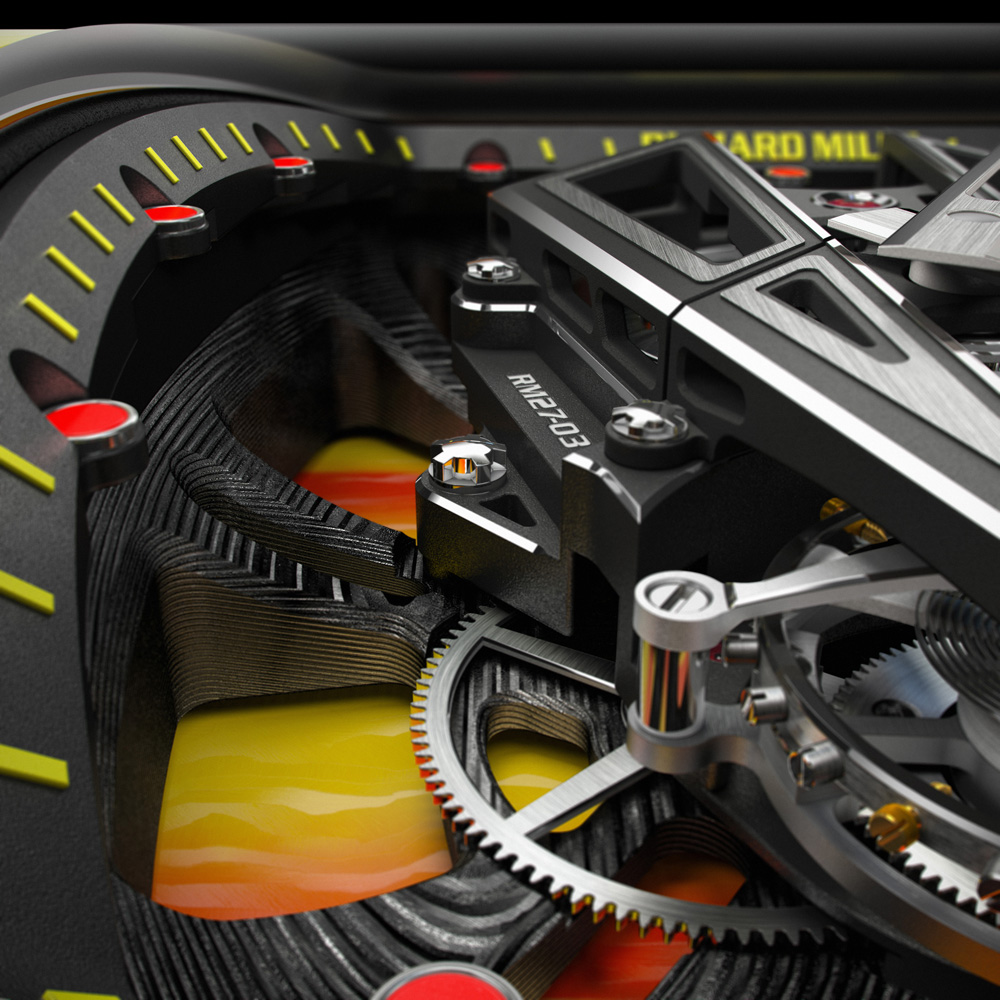

The RM27-03 caliber incorporates an extraordinary tourbillon that can withtand shocks up to 10,000 g’s and represents a new threshold. In addition to years of research and development, the watch has undergone hundreds of hours of pendulum impact testing. Finally, the ultra-light tourbillon caliber is further skeletonized and made with fewer components to reduce weight. A rapid winding barrel offers 70 hours of power reserve. Naturally, the components are magnificently finished, and the bridges, wheel and tourbillon emulate the horns of a bull — a symbol of Spain and Rafa’s chosen emblem. The torque-limiting crown for winding is in the shape of a tennis ball. Just 50 pieces will be made.

TECHNICAL SPECIFICATIONS OF THE RM 27-03 TOURBILLON RAFAEL NADAL

Limited edition of 50 pieces.

CALIBRE RM27-03: manual winding tourbillon movement with hours and minutes. Dimensions: 47.77 x 40,30 x 12.75 mm.

POWER RESERVE: 70 hours (±10%).

UNIBODY BASEPLATE IN CARBON TPT®

The unibody baseplate caseband construction of the RM 27-03 is machined from Carbon TPT®. The bezel and caseback are assembled directly on the baseplate, which is described as ‘unibody’—a type of racing-car construction that ensures maximum rigidity and greater resistance to impacts.

Carbon TPT® consists of multiple layers of parallel filaments obtained by separating carbon threads. With a maximum thickness of 30 microns, the Carbon TPT® layers are saturated with resin then piled onto a special machine that modifies the orientation of the fibre between each layer by 45°. Once it has been heated to 120°C and subjected to a pressure of 6 bars, the Carbon TPT® is machined at Richard Mille’s parts factory. Carbon TPT® is renowned for its excellent resistance to micro-cracks and splits.

The skeletonised Carbon TPT® baseplate is a feat of machining. A master component of the RM 27-03, it has been subjected to a full battery of extreme approval tests in order to optimise its mechanical properties.

BRIDGES IN GRADE 5 TITANIUM

Grade 5 titanium is a biocompatible, highly corrosion-resistant and remarkably rigid alloy, which enables the gear train to function effortlessly. The alloy is 90% titanium, 6% aluminium and 4% vanadium. This combination further increases its mechanical properties, which explains its frequent use in the aerospace, aeronautical and automobile industries.

Like the baseplate, the bridges of the RM 27-03 calibre were subjected to intensive and comprehensive approval tests in order to optimise their resistance properties.

FREE SPRUNG BALANCE WITH VARIABLE INERTIA

A free sprung balance with variable inertia and a terminal-curve spring guarantees greater reliability in case of impacts and during movement assembly and disassembly, thus achieving better chronometric results over time.

FAST ROTATING BARREL (6 hours per revolution instead of 7.5 hours)

This type of barrel has the following advantages:

– The phenomenon of periodic internal mainspring adhesion is significantly diminished and performance is thus enhanced, – It provides an excellent delta of the mainspring curve. The choice is determined by the ideal power reserve/performance/regularity ratio

BARREL PAWL WITH PROGRESSIVE RECOIL

This device permits an appreciable winding gain (circa 20%), especially during the start of winding. It also promotes the even distribution of the mainspring’s internal tension.

WINDING BARREL TEETH AND CENTRE-WHEEL PINION WITH CENTRAL INVOLUTE PROFILE

The central involute profile of the winding barrel teeth provides an optimal pressure angle of 20°, which promotes effective rotary motion and compensates for possible variations in the operation of the going train. This, in turn, ensures excellent torque transmission and a distinct improvement in performance.

OTHER FEATURES

– Movement dimensions: 29.30 x 29.60 mm • Thickness: 7.10 mm

• Tourbillon diameter: 12.30 mm

• Balance diameter: 10.00 mm

• Number of jewels: 19

• Balance: Glucydur, 2 arms and 4 setting screws

• Moment of inertia 11.50 mg•cm2, angle of lift 53°

• Frequency: 21,600 vph (3 Hz)

• Balance spring: elinvar by Nivarox®

• Shock absorbers: KIF Elastor KE 160 B28

• Barrel shaft: nickel-free Chronifer (DIN x 46 Cr 13 + S), with the following characteristics: stainless – antimagnetic – suitable for tempering

CASE IN QUARTZ TPT®

The front and back bezels of the RM 27-03 are made from Quartz TPT®, a groundbreaking new material designed and developed by Richard Mille in partnership with North Thin Ply Technology.

Quartz TPT® is composed of layers of parallel filaments obtained from separating silica threads. These layers, no thicker than 45 microns, are saturated in a yellow or red resin developed specially for Richard Mille, then inserted using an automatic positioning system that changes the orientation of the fibre between each layer by 45°.

It is then heated to 120°C and subjected to a pressure of 6 bars in an autoclave similar to those used to make aeronautical components, before the material is ready for machining on a CNC machine at Richard Mille’s manufacturing facilities. Machining unveils the various Quartz TPT® layers at random, ensuring that each machined part is unique.

Quartz fibres are generally used for very high performance applications due to their resistance to high temperatures and their strength.

The complete case construction is water-resistant to 50 metres thanks to two Nitril O-rings, is assembled using 12 spline screws in grade 5 titanium and 316L stainless steel washers.

TORQUE LIMITING CROWN

The crown is in Quartz TPT®. This additional security system prevents from accidental overwinding, which could cause damage to the winding stem or place extreme pressure on the mainspring barrel.

CRYSTAL: In sapphire (1800 Vickers) with anti-glare treatment (2 sides) Thickness: 1.20 mm and 4.09 mm at the edges

The crown of the Richard Mille RM27-03 Rafael Nadal Tourbillon is made to resemble a tennis ball.